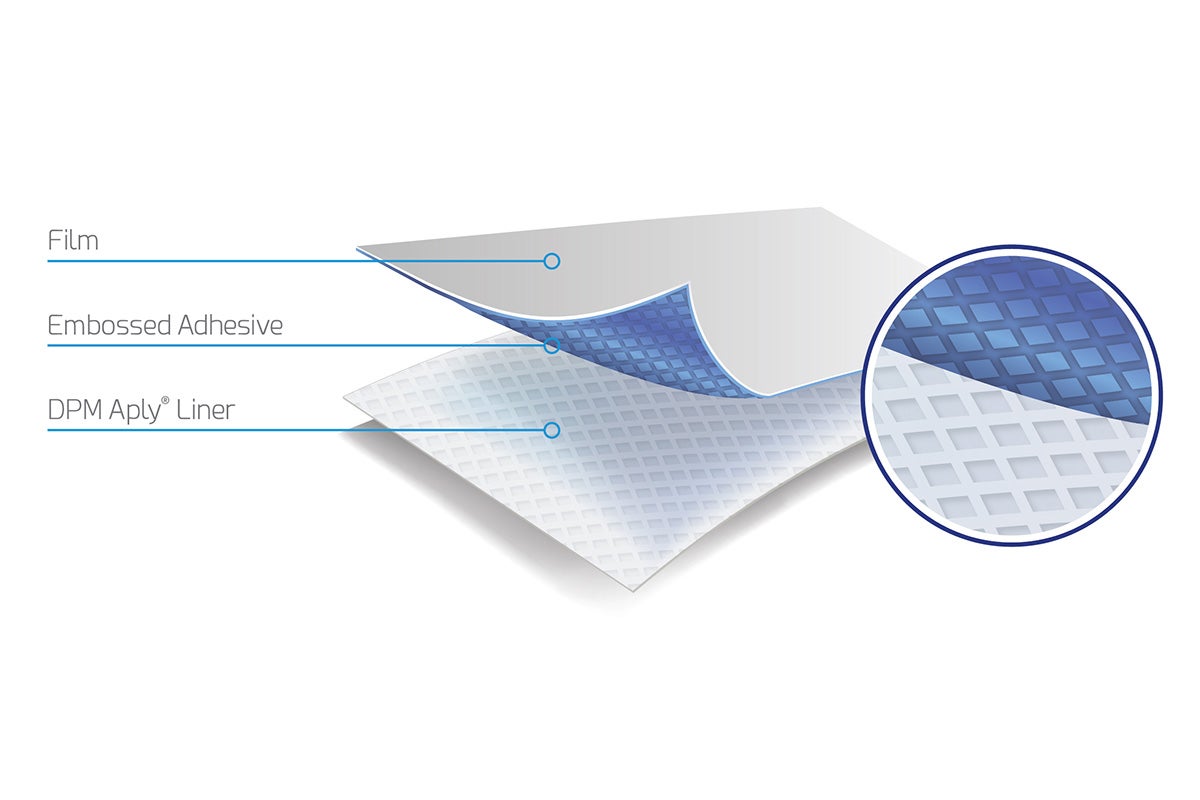

Spencer, Mass. – June 28, 2023 - Flexcon Global, an innovator in adhesive coating and laminating, today announced the launch of Flexcon® DPM Aply® with Air Egress Liner, for the North American market. DPM Aply® is a series of durable labeling products with air egress channels in the adhesive imparted by the liner to facilitate smooth bubble-free label application on challenging surfaces such as molded plastics and powder-coated paints.

This innovative combination of Flexcon’s durable labeling and nameplate films, including vinyls, polypropylenes, and polyesters, with a high-performance permanent solvent-based acrylic adhesive, and a high-performance air-egress liner design yields the highest performing narrow-format industrial and durable labeling solutions in the marketplace.

DPM Aply® products are designed for narrow-format brand identification labels/nameplates and safety/hazard/instructional labels for Consumer Durables, Automotive, and Industrial applications. Four of the six products are UL-recognized and easily adoptable into print providers’ UL files. Flat UL adoption fees are reimbursable via Flexcon’s UL Adoption Program.

“Label aesthetics are a major concern for OEMs in these markets,” says Jason Berthiaume, Product Manager, Flexcon. “Trapped air under the label caused by poor application can lead to unacceptable appearance and label failures which, in turn, can send a negative message about the quality of the product.”

The line offers these benefits:

• Easy Application Without Bubbles. The embossed liner creates air egress channels in the adhesive that eliminate bubbles, wrinkles, and rework, yielding a superior appearance.

• Smoother Appearance. Lower depth of air egress channels compared to competitive products translates into a smoother label appearance, especially with silver polyester.

• Outdoor Durability. Vinyl and polypropylene films provide five-year exterior durability based on 2500 hours Xenon Arc for meeting long-term durable label needs. Polyesters provide two years.

• Excellent Adhesion. Industry proven acrylic adhesive bonds well to low- and high-surface energy plastics, painted metal, powder-coated paint, polycarbonate, and fiberglass with no label lift.

• No Curling On Press. Layflat 90 lb. air egress liner provides optimal converting performance, ideal for roll-to-sheet and sheet-form converting for narrow-format digital printing applications.

• Sustainability. Durable polypropylene options enable printers and end users to meet sustainability goals without sacrificing performance.

UL-recognized options in the DPM Aply® line are currently in inventory in 60” master rolls and ready to be finished and shipped throughout North America.

About Flexcon

Flexcon Global is a leader in coated and laminated films and adhesives used as functional components in manufactured goods and in graphics applications. A family-owned company for over 68 years, Flexcon serves as a development partner to engineers and designers to bring their innovative ideas from concept to reality, for markets such as transportation, electronics, industrial, healthcare, and construction & energy, with a focus on improving human lives through emerging technology. Headquartered in Spencer, MA, USA, the company has operations and distribution throughout North America, Europe and Asia. For more information, visit Flexcon.com, follow Flexcon on LinkedIn, or call +1-508-885-8200.

Media Contact:

Amanda Monette, Marketing Communications

Flexcon Company, Inc.

508-885-8459

amonette@flexcon.com